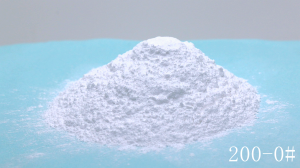

Factory For China White Fused Alumina Corundum with Higher Bulk Density Higher Whiteness

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Factory For China White Fused Alumina Corundum with Higher Bulk Density Higher Whiteness, We have now ISO 9001 Certification and qualified this item .in excess of 16 years experiences in manufacturing and designing, so our items featured with best quality and competitive selling price. Welcome cooperation with us!

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for China White Aluminum Oxide, White Corundum Abrasive, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The physical and chemical properties

Brown corundum sand has shell fracture and sharp edge, which can form new edges and edges in continuous grinding and grading, making its grinding ability better than other abrades. In particular, it has the advantages of high hardness, large ratio, stable chemical properties and its unique self-sharpening become the first choice for abrasive blasting process; At the same time is sandblasting rust cleaning workpiece, grinding and polishing of the ideal material.

use

Workpiece material sand blasting process requirements

Stainless steel surface decontamination, welding slag and matte effect

Iron workpiece rust, decontamination, in addition to the oxide, increase the coating, coating adhesion

Aluminum work piece to scale, surface strengthening, finishing effect

Copper workpiece degreasing effect

Glass products crystal frosted, engraved design

Matt effect of plastic products (hardwood products)

Denim and other special fabric plush processing and effect patterns

Composite indicator

Physicochemical properties and particle size parameters of brown corundum sand:

| Level | Chemical composition content (%) | Producable size | |||

| Al2O3 | Fe2O3 | SiO2 | TiO2 | ||

| Level 1 | 92-96 | 0.2-1.0 | 1.0-3.0 | 1.5-3.8 | 0-1-3-5-8mm 100#-0 200#-0 320#-012# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220#W63 W50 W40 W28 W20 W14 W10 W7 |

| Level 2 | 80-90 | 6-10 | 1.5-4 | 2-4 | 0-1mm 1-3mm 3-5mm 5-8mm12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# |

| Level 3 | 70-80 | 8-15 | 2-5 | 3-5 | |

| Level 3 | 50-70 | 12-20 | 15-25 | 4-6 | |

| Physical properties |

Chemical properties: Neutral (PH=7) Refractoriness: 1900 Bulk density :1.53-1.99g/cm3 True density: 3.95 to 3.97 g/cm3 Mohs hardness :9.0

|

||||

| Use | Refractory materials, ramming miscellaneous materials, coating, charge, nozzle material, sandblasting, water knife cutting, grinding, surface treatment, surface rust removal, polishing, etc | ||||

Our organization aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Factory For China White Fused Alumina Corundum with Higher Bulk Density Higher Whiteness, We have now ISO 9001 Certification and qualified this item .in excess of 16 years experiences in manufacturing and designing, so our items featured with best quality and competitive selling price. Welcome cooperation with us!

Factory For China White Aluminum Oxide, White Corundum Abrasive, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.