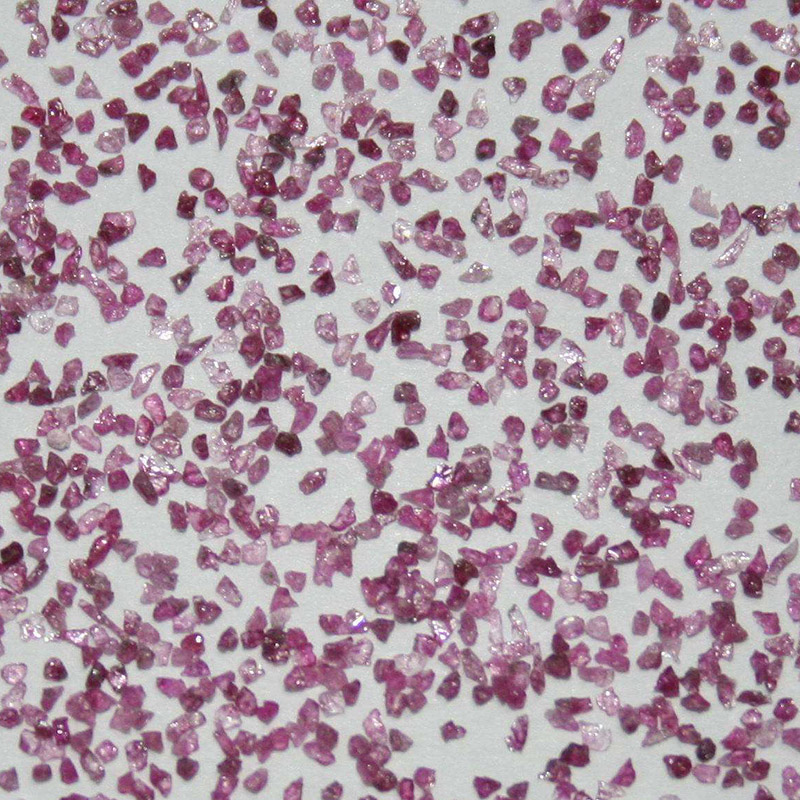

Chrome corundum (also known as pink corundum) is made by chemical reaction of metallurgical chrome-green and industrial alumina at high temperature above 2000 degrees. A certain amount of chromium oxide is added during the smelting process, which is light purple or rose.

Chromium corundum excels in comprehensive performance including high hardness, high toughness, high purity, excellent self-sharpening, strong grinding ability, low heat generation, high efficiency, acid and alkali resistance, high temperature resistance, and good thermal stability.

The addition of chemical element Cr in chrome corundum improves the toughness of its abrasive tools. It is similar to white corundum in hardness but higher in toughness. Abrasive tools made of chrome corundum have good durability and high finish. It is widely used in abrading, grinding, polishing, precisely casting sand, spraying materials, chemical catalyst carrier, special ceramics and so on. Applicable fields include: measuring tools, machine tool spindles, instrument parts, precise grinding in threaded production and model.

The chrome corundum has high viscosity and good permeability due to the chromium oxide-containing glass component, which can largely prevent the erosion and penetration of molten slag. It is also widely used in high temperature fields with harsh environment, including non-ferrous metallurgy furnaces, glass melting furnaces, carbon black reactors, garbage incinerators and refractory castables.

Chromium corundum products

Physical and chemical indicators

| Chromium oxide content | Low chrome

0.2 --0.45 |

The chromium

0.45--1.0 |

High chromium

1.0--2.0 |

Granularity range

| AL2O3 | Na2O | Fe2O3 | |

| F12--F80 | 98.20min | 0.50max | 0.08max |

| F90--F150 | 98.50min | 0.55max | 0.08max |

| F180--F220 | 98.00min | 0.60max | 0.08max |

True density: 3.90g/cm3 Bulk density: 1.40-1.91g/cm3

Microhardness: 2200-2300g/mm2

Chrome Corundum Macro

| PEPA | Average grain size(μm) |

| F 020 | 850 – 1180 |

| F 022 | 710 – 1000 |

| F 024 | 600 – 850 |

| F 030 | 500 – 710 |

| F 036 | 425 – 600 |

| F 040 | 355 – 500 |

| F 046 | 300 – 425 |

| F 054 | 250 – 355 |

| F 060 | 212 – 300 |

| F 070 | 180 – 250 |

| F 080 | 150 – 212 |

| F 090 | 125 – 180 |

| F 100 | 106 – 150 |

| F 120 | 90 – 125 |

| F 150 | 63 – 106 |

| F 180 | 53 – 90 |

| F 220 | 45 – 75 |

| F240 | 28 – 34 |

Typical physical analysis

| Al2O3 | 99.50 % |

| Cr2O3 | 0.15 % |

| Na2O | 0.15 % |

| Fe2O3 | 0.05 % |

| CaO | 0.05 % |

Typical physical properties

| Hardness | 9.0 mohs |

| Color | pink |

| Grain shape | angular |

| Melting point | ca. 2250 °C |

| Maximum service temperature | ca. 1900 °C |

| Specific gravity | ca. 3.9 – 4.1 g/cm3 |

| Bulk density | ca. 1.3 – 2.0 g/cm3 |