Wholesale Brown Alumina Suppliers – Black corundum brown corundum section sand blasting electric fused corundum – Wanyu

Wholesale Brown Alumina Suppliers – Black corundum brown corundum section sand blasting electric fused corundum – Wanyu Detail:

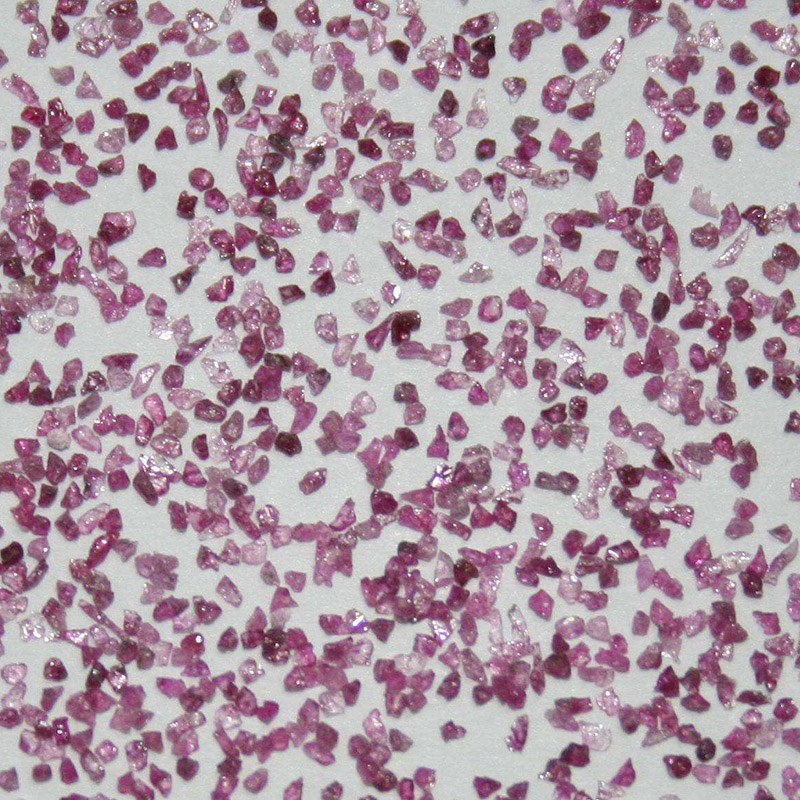

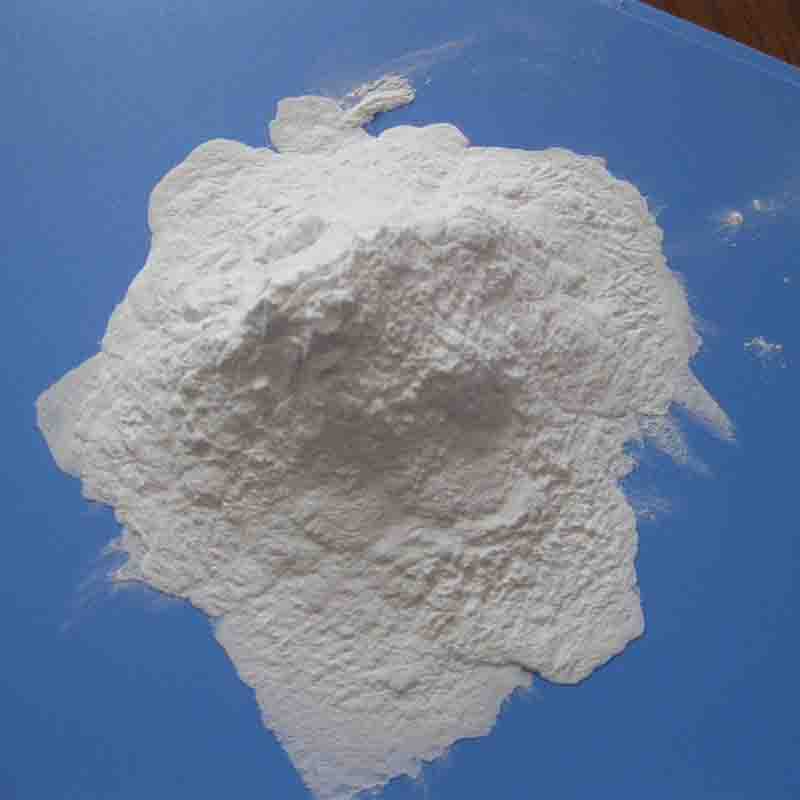

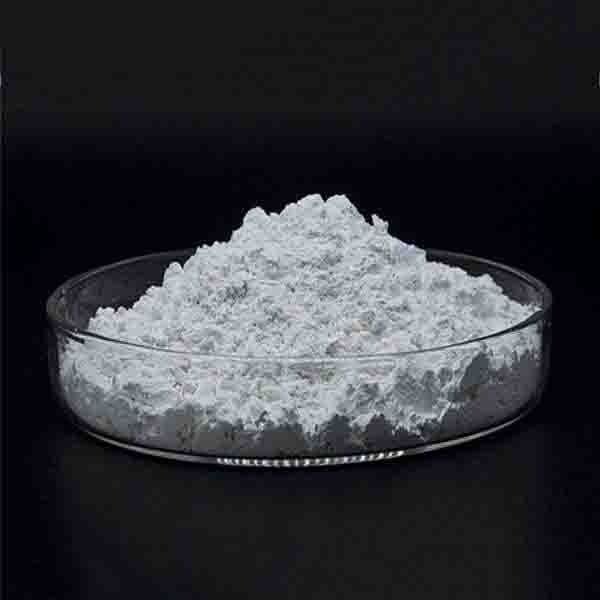

White corundum

What is the main method of white corundum grain size sand used for polishing materials?

White corundum is divided into white corundum block, white corundum section sand, white corundum grain size sand and fine powder

The white corundum section sand is produced by using high-quality white corundum blocks through various processes such as crushing, shaping and screening. The white corundum section sand has the characteristics of acid and alkali corrosion resistance and high toughness.

Features: white, harder and more brittle than brown corundum, strong cutting force, good chemical stability, and good insulation. It has the characteristics of high purity, good hardness, and strong wear resistance, so it is often used as an abrasive, and also used for fine and grinding stainless steel and other materials.

Chemical indexes of white corundum

| Chemical composition | AL2O3% | SiO2% | Fe2o3% | Na2O% | L.O.I% | Volume densityg/cm3 |

| White corundum index | ≥99.5% | ≤0.1% | ≤0.1% | ≤0.35% | 0.1 | 3.50 |

| White corundum powder | ≥99.5% | ≤0.1% | ≤0.1% | ≤0.35% | 0.1 | 3.50 |

White corundum is made of high-quality alumina powder, and the melting temperature exceeds 2000 degrees. It has high purity, good self-sharpening, acid and alkali corrosion resistance, high temperature resistance and stable thermal performance. The hardness is slightly higher than that of brown corundum, and the toughness is slightly lower than that of brown corundum. High hardness, high particle density, good single particle roundness, color: white, no impurities, to ensure the color and transparency of the wear-resistant layer or wear-resistant paper, uniform particle size distribution, uniform shape of the single particle, with the smallest possible maximum Abrasion resistance.

1. Liquid polishing: Liquid polishing is based on the high-speed flow of liquid and the erosion of the surface of the workpiece with white corundum grit to achieve the purpose of polishing.

Commonly used methods are: diamond sand spraying processing, fluid dynamic grinding processing. Fluid dynamic grinding is hydraulically driven, allowing the liquid medium carrying white corundum abrasive particles to flow back and forth at high speed on the surface of the workpiece through the sandblasting gun. The liquid medium is mainly made of special compounds, has good fluidity under lower pressure, and is mixed with white corundum powder.

2. Mechanical polishing: Mechanical polishing refers to a polishing method that removes the convex part of the polishing material from the plastic deformation of the cutting surface. Generally speaking, the polishing film is mainly made by hand. Special parts such as rotating surfaces can use auxiliary tools such as turntables, and ultra-precision polishing can use high-quality polishing methods.

3. Chemical polishing: Chemical polishing makes the micro-protruding part of the material surface more soluble in the chemical medium than the concave surface, so as to obtain a smooth surface. The main advantage of this method is that it can polish workpieces with complex shapes without complicated equipment, and can polish multiple workpieces at the same time, and the processing efficiency is high.

4. Magnetic grinding and polishing: Magnetic green silicon carbide is used for magnetic grinding and polishing to form white corundum sand under the action of a magnetic field. The method has the advantages of high processing efficiency, good quality, easy control of process conditions and good working conditions.

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Wholesale Brown Alumina Suppliers – Black corundum brown corundum section sand blasting electric fused corundum – Wanyu , The product will supply to all over the world, such as: moldova, Pakistan, Luxembourg, We are committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!