High-Quality Fused Alumina Manufacturer – Alumina powder and α-type alumina powaer – Wanyu

High-Quality Fused Alumina Manufacturer – Alumina powder and α-type alumina powaer – Wanyu Detail:

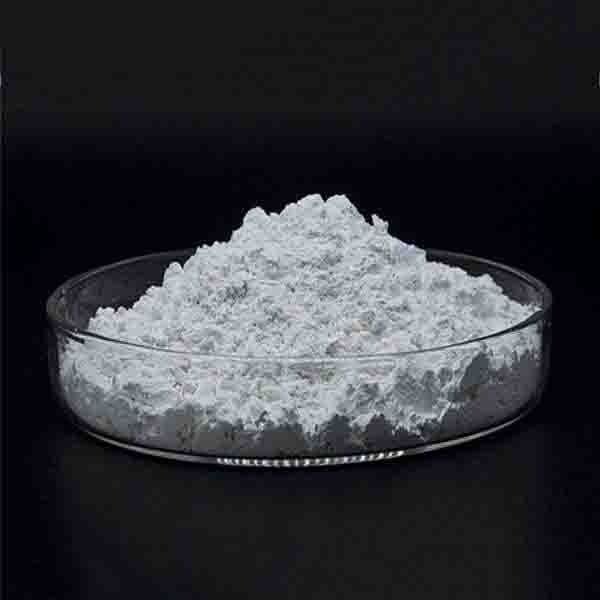

Five characteristics of high-purity alumina powder

1. Chemical resistance;

2. High-purity alumina, the alumina content is greater than 99%;

3. High temperature resistance, normal use at 1600℃, short-term 1800℃;

4. Resistant to sudden cold and heat, not easy to burst;

5. It adopts grouting and has high density.

1. Use of α-type alumina powder

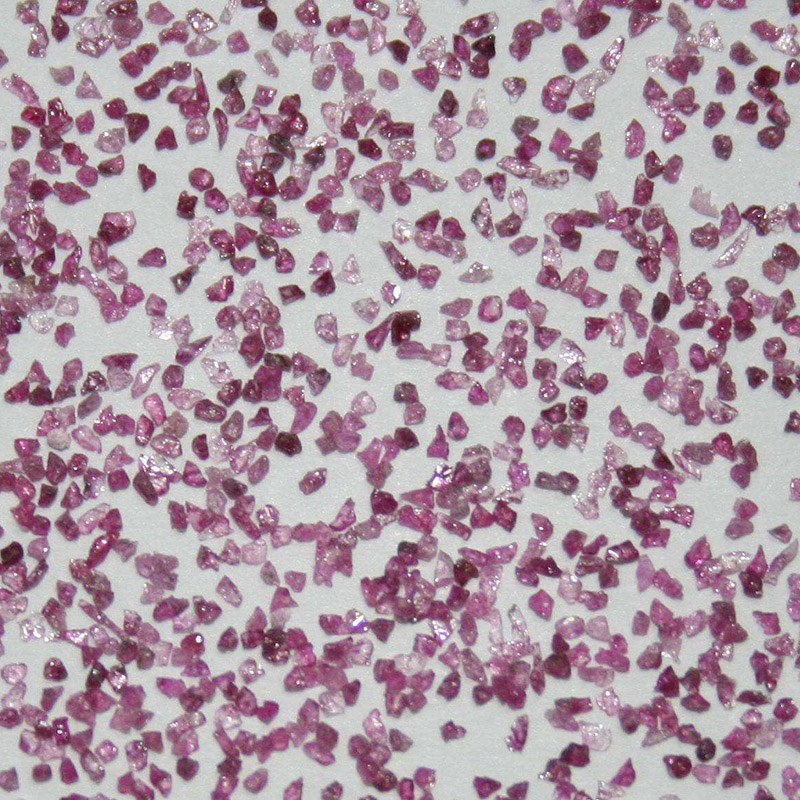

In the crystal lattice of α-type alumina powder, oxygen ions are closely packed in hexagons, and Al3+ is symmetrically distributed in the octahedral coordination center surrounded by oxygen ions. The lattice energy is very large, so the melting point and boiling point are very high. α-type oxidation Aluminum is insoluble in water and acid. It is also called aluminum oxide in industry. It is the basic raw material for making metal aluminum; it is also used to make various refractory bricks, refractory crucibles, refractory tubes, and high temperature test instruments; it can also be used as abrasives and flame retardants. Agents, fillers, etc.; high-purity α-type alumina is also the raw material for the production of artificial corundum, artificial ruby and sapphire; it is also used for the production of modern large-scale integrated circuits.

Activated alumina has selective adsorption capacity for gas, water vapor and some liquid moisture. After the adsorption is saturated, it can be revived by heating at about 175-315°C to remove water. Adsorption and resurrection can be performed multiple times. In addition to being used as a desiccant, it can also adsorb the vapor of lubricating oil from polluted oxygen, hydrogen, carbon dioxide, natural gas, etc. It can also be used as catalyst and catalyst carrier and chromatography carrier.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the toughness by quality". Our firm has strived to establish a highly efficient and stable workers workforce and explored an effective high-quality management system for High-Quality Fused Alumina Manufacturer – Alumina powder and α-type alumina powaer – Wanyu , The product will supply to all over the world, such as: Cologne, Melbourne, Jordan, Our company mission is that providing high quality and beautiful products with reasonable price and strive to gain 100% good reputation from our clients. We believe Profession achieves excellence! We welcome you to cooperate with us and grow up together.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!