Alumina 99.5% white corundum sand fine powder capacitive crystal – Wanyu

Alumina 99.5% white corundum sand fine powder capacitive crystal – Wanyu Detail:

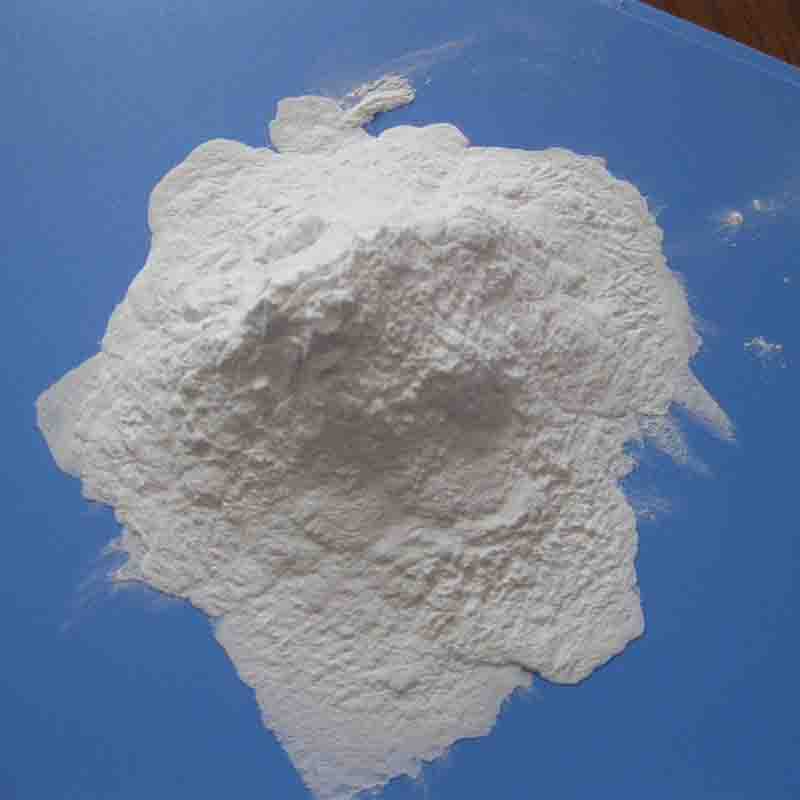

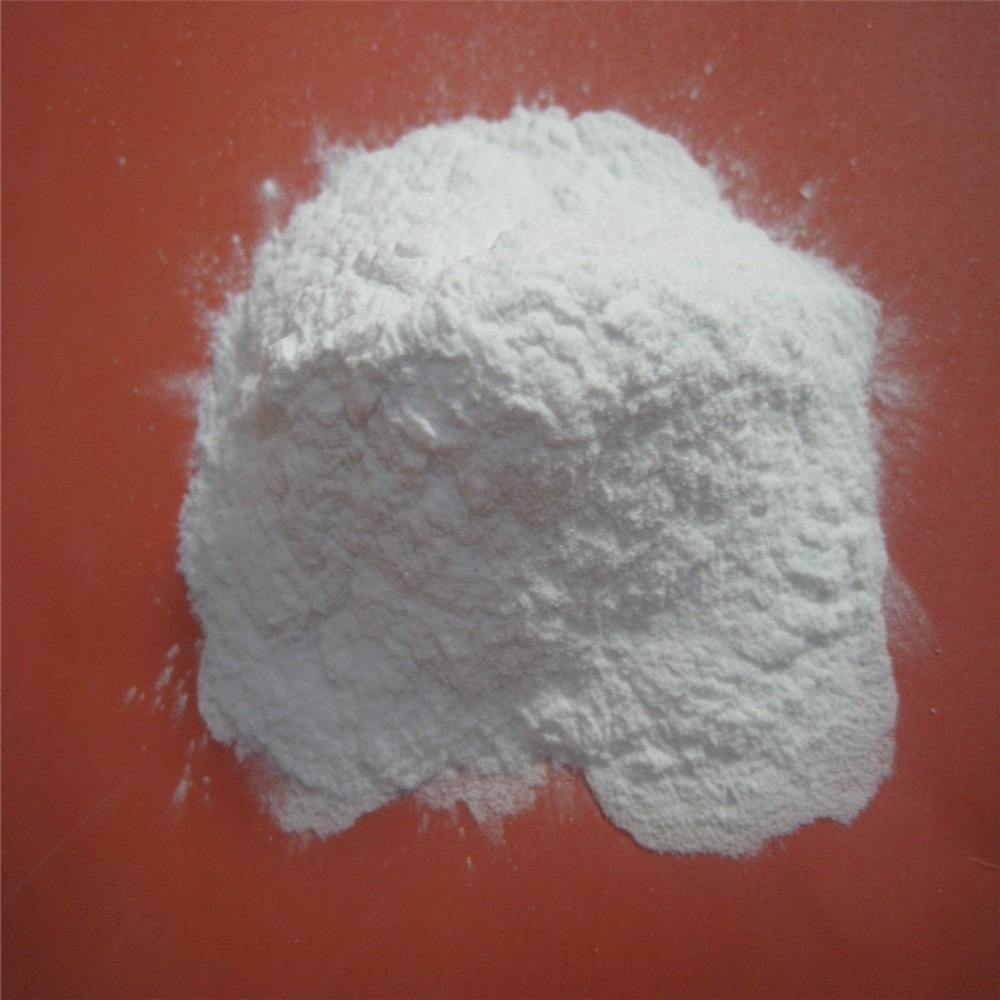

White corundum fine powder

The fine white corundum powder is made from alumina powder and smelted at high temperature. It is white. The hardness is slightly higher than that of brown corundum, and the toughness is slightly lower. The white corundum powder produced by our company has the characteristics of stable product quality, uniform particle size composition, low magnetic content, high bulk density, high hardness, good toughness, and high cleanliness.

White corundum is fine powder, white, with strong cutting power. It has good chemical stability and good insulation. Scope of application: wet or dry blasting sand, suitable for ultra-precision grinding and polishing in the crystal and electronic industries.

White corundum powder is also often used as a refractory material, because fine white corundum powder is one of the high-purity corundum materials, especially when used in refractory materials, which can significantly improve the performance of refractory materials.

When white corundum powder is used instead of alumina powder, the high temperature resistance of the refractory is not reduced or improved, and the linear change rate of the refractory is also increased. It is because adding an appropriate amount of white corundum powder can improve the compactness of the castable, and the white corundum can also form mullite with the silica powder at high temperature, thereby improving the high-temperature strength of the castable.

Chemical indexes of white corundum

| Chemical composition | AL2O3% | SiO2% | Fe2o3% | Na2O% | L.O.I% | Volume densityg/cm3 |

| White corundum index | ≥99.5% | ≤0.1% | ≤0.1% | ≤0.35% | 0.1 | 3.50 |

| White corundum powder | ≥99.5% | ≤0.1% | ≤0.1% | ≤0.35% | 0.1 | 3.50 |

Product use of white corundum powder

1. It can be used in all kinds of sandblasting and grinding operations;

2. Atomized aesthetic processing of Polly or acrylic artwork;

3. Sandblasting in the TV screen manufacturing process;

4. Cutting of silicon wafer;

5. Clean sand blasting in the middle of the tooth mold;

6. Molding sand for precision casting;

7. Advanced refractory materials and other ceramic additives;

8. Advanced grinding and polishing.

Product detail pictures:

Related Product Guide:

All we do is always involved with our tenet " Consumer initial, Trust first, devoting within the food stuff packaging and environmental defense for Alumina 99.5% white corundum sand fine powder capacitive crystal – Wanyu , The product will supply to all over the world, such as: kazan, Muscat, Somalia, We believe with our consistently excellent service you can get the best performance and cost least products from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.